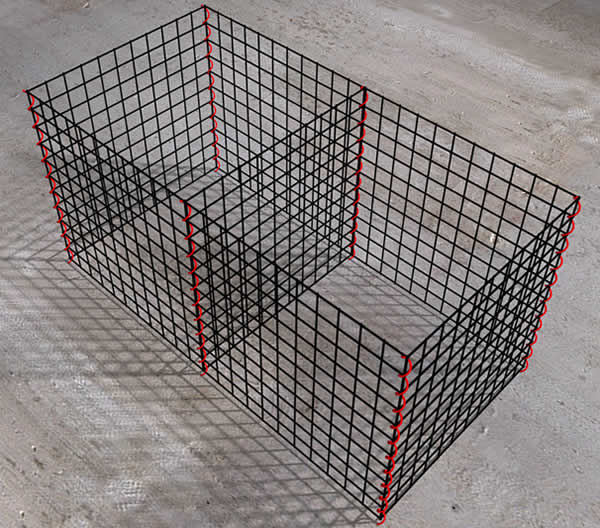

Gabions units shall be assembled in accordance with the manufacturer's instructions, the procedure shown on the drawings and the tolerances.

Laying plans shall be provided by the Contractor, for the approval of the Engineer, a minimum of 28 days prior to laying the baskets, giving details of how the gabions will be placed, including:

- elevation and number of each row of baskets

- orientation of basket (and axis of twist of mesh)

- layout of mesh reinforcement

- number and location of connections between mesh and gabion baskets

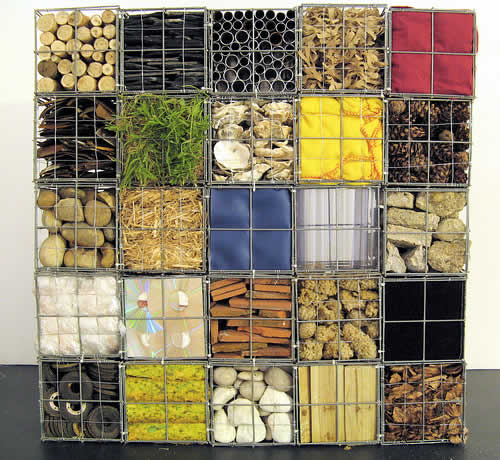

The box gabions and mattress gabions unit shall be filled with stone in such a manner as to minimise the number and size of voids and to achieve a dense, compact compartment of well graded stone. Gabions shall be filled to approximately 50 to 75mm above the top edge of the diaphragms, such that the lid is under tension when it has been levered into position and laced to the ends and tops of the diaphragms.

Gabion units shall, where appropriate, be maintained square and with vertical sides during filling. Internal tie wires shall be inserted and units shall be tensioned and then filled in layers in accordance with the manufacturer's instructions and construction sequence shown in the drawings. Gabion units shall be constructed so as to maintain tightness of mesh. Diaphragms shall be tightly laced to the top of the gabion, to ensure stone cannot migrate internally over the diaphragm. Where gabions are constructed above each other then, as directed by the Engineer, then each row shall be transposed laterally, so that the sides of baskets are not vertically above each other.

The diaphragms in mattresses shall be kept vertical, where appropriate, and filling shall proceed from the bottom of the slope to the top.

On site connections shall be by a minimum of two turns of binding wire at 125mm centres with a minimum length of binding wire sufficient to bind 1000mm length of connection. Binding wire shall comply with Clause 242.2. Alternate methods of onsite connection may be used subject to the approval of the Engineer, and provided that they provide at least the same strength and flexibility as the specified method.

It is essential for the stability and effectiveness of the gabion scour protection to the downstream face of the embankment that every basket is securely connected to all adjacent baskets and to the gabion mesh reinforcement. The Contractor shall therefore include details in his quality control program of how he shall ensure and check that onsite connections are carried out in accordance with the specification, including details of records that will be kept relating to onsite connections.

Mechanical equipment may only be used for filling gabion units where the Engineer is satisfied that the results are equivalent to filling by hand. Where mechanical equipment is accepted then a back-acter shall be used with a bucket no wider than the width of one compartment.

Where triangular or other irregular shaped gabions are required proposed laying plans shall be submitted at least two weeks in advance of the proposed works to the Engineer for his approval, and shall include:

- plans and sections as necessary to show original and modified shape of gabion;

- details of how modified shape will be achieved;

- details of lacing between mesh sections.

Whenever possible shaping shall be carried out by folding of the mesh, with tying of the folds as for connections between baskets. Where this is not possible, then on-site cutting may be used subject to the approval of the Engineer and to a satisfactory method of lacing the gabions to restore their original strength.

The Contractor shall ensure that gabions in place in the works are not damaged by plant and not contaminated by any foreign materials or debris. In the event of damage or contamination the Contractor shall at his own expense, as directed by the Engineer either make good the damage or install replacement gabions.

Where gabions abut against concrete work or similar, they shall either be anchored to them or be well staked, to ensure they cannot pull away from the structure.