When using lacing wire, cut off a length of wire approximately 1,5 times the length of the edge to be tied. The maximum length of the edge to be tied at one time shall not exceed 1 m. Longer edges shall be joined by several lengths of wire.

Lacing wires shall be secured around the selvedge wire or heavier edge wire, where present, by looping and twisting the lacing wire around itself.

Proceed tying with alternate double and single loops.

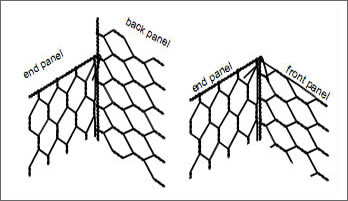

Double loops shall be made at in tervals not greater than 300 mm. All panels shall be pulled tightly together during the tying operation. Pliers may be used to create tight joints.

The other end of the lacing wire shall be secured by again looping and twisting the wire around itself.

When using lacing wire to assemble the units, care should be taken to avoid damaging the wire coating.

When steel ring fasteners are used, the custom made is required and is available for hire.

Rings shall be installed at the top and the bottom connections of the end and centre diaphragms and then a maximum spacing of 100 mm along all edges shall be used.